That white, crusty buildup on your battery terminals isn’t just ugly—it’s slowly killing your car’s electrical system. Every day you delay cleaning battery corrosion, you’re risking a dead vehicle, expensive repairs, and being stranded at the worst possible moment. The good news? You can eliminate this corrosion in under 30 minutes with common household items.

This guide walks you through the exact process professionals use to restore battery connections and prevent future corrosion. You’ll learn safety essentials, proven cleaning techniques, and long-term prevention strategies that save you hundreds in repair costs. By the end, you’ll know exactly how to clean corrosion off car battery cables safely and effectively.

Why Your Car Battery Terminals Turn White and Crusty

Battery corrosion appears as white, ashy residue accumulating on battery posts and cable terminals. This buildup forms when hydrogen gas from battery acid reacts with surrounding particles, accelerated by engine heat cycles. Summer temperatures intensify this process, making warm months prime time for severe corrosion.

Beyond cosmetic damage, corrosion creates electrical resistance that starves your vehicle of power. You’ll notice dim headlights, slow engine cranking, and eventual complete electrical failure. In extreme cases, corrosion can damage your A/C system, radio, and the car’s entire computer network. Ignoring that white powder means risking a dead battery when you need your car most.

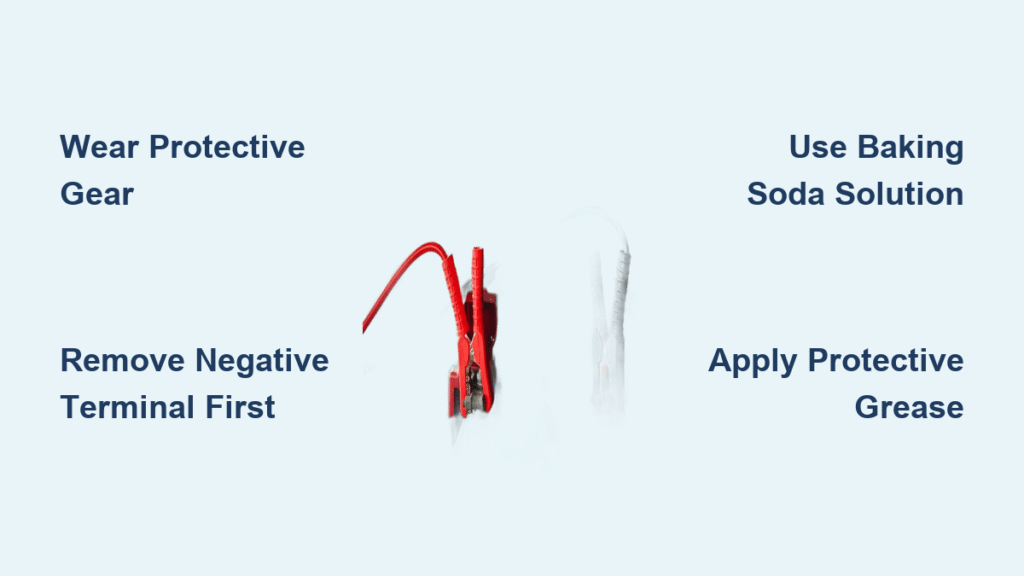

Critical Safety Gear for Battery Corrosion Removal

Battery acid causes severe chemical burns on contact. Before touching anything, gear up properly:

Required Protection:

– Chemical-resistant gloves that cover your wrists

– Safety goggles that seal around your eyes

– Old clothing you don’t mind ruining (acid eats through fabric)

Pre-Cleaning Inspection:

– Check for acid leaks on the battery tray

– Look for swollen battery case or damaged cables

– Identify if cables require replacement instead of cleaning

Stop immediately if you find severe damage or leaks. These conditions need professional attention, not DIY cleaning. One drop of battery acid can burn through skin in seconds—don’t risk it without proper protection.

Remove Battery Cables Without Creating Electrical Hazards

Removing the negative terminal first prevents dangerous electrical shorts. Your tool selection depends on battery type:

- Side-post batteries: 5/16-inch wrench

- Top-post batteries: ⅜-inch or metric wrench

Critical Warning: Keep your wrench away from the positive terminal while removing the negative. If the metal touches both terminals simultaneously, you’ll create a short circuit that can melt tools and cause sparks. If cables won’t budge due to corrosion, don’t force them. Apply penetrating oil and wait, or seek professional help.

For newer vehicles with sensitive electronics, connect a battery tender before disconnection to preserve computer settings during cleaning. This $20 tool prevents your radio from resetting and maintains your car’s adaptive systems.

Create the Perfect Corrosion-Removing Solution

Make this proven alkaline mixture to neutralize battery acid safely:

Primary Formula:

– 1 tablespoon baking soda

– 1 cup warm water

The solution bubbles on contact with corrosion—this fizzing indicates successful acid neutralization. For heavy corrosion, specialized battery cleaner spray works faster, but baking soda remains the safest, most effective option because it won’t damage surrounding components.

Required Cleaning Tools:

– Battery brush (dual-ended for posts and clamps)

– Designated toothbrush (never reuse for teeth)

– Clean microfiber rags

– Penetrating oil (WD-40)

– Petroleum jelly or silicone grease

Deep Clean Corroded Battery Terminals in Three Phases

Phase 1: Neutralize and Loosen Surface Corrosion

- Apply baking soda solution directly to corroded areas using a spray bottle or rag

- Wait for bubbling to confirm acid neutralization (about 30 seconds)

- Scrub terminals thoroughly with appropriate brush using firm, circular motions

- Work persistently but avoid metal damage—replace damaged terminals if necessary

This initial cleaning removes surface corrosion and prepares the terminals for deeper cleaning. Don’t skip the waiting step—the chemical reaction is essential for complete neutralization.

Phase 2: Remove Terminals for Complete Cleaning

- Spray penetrating oil on corroded terminal bolts and let sit for 5-10 minutes

- Remove terminal bolts gently—never force severely corroded connections

- Lift terminals off posts carefully to avoid breaking brittle cables

- Clean interior surfaces of terminals and exterior of battery posts completely

- Replace damaged terminals using replacement kits when necessary

For stubborn connections, tap the wrench handle gently with a rubber mallet—never use excessive force. If a terminal breaks during removal, you’ll need a replacement kit immediately.

Phase 3: Final Rinse and Preparation

- Rinse all surfaces with clean water to remove baking soda residue

- Dry completely using clean rags—moisture accelerates future corrosion

- Inspect thoroughly for remaining corrosion using a flashlight

- Apply protective coating immediately after drying to prevent recontamination

Pro Tip: Use compressed air to blow out hard-to-reach areas inside terminal clamps. Any moisture left behind will restart the corrosion process immediately.

Reconnect Battery Cables Without Causing Electrical Damage

Reattach cables in reverse order of removal:

- Positive terminal first – slide it firmly onto the post

- Tighten securely using the proper wrench size (don’t over-torque)

- Negative terminal last – ensure it clicks into place with solid contact

Check your connection by gently tugging on each cable—there should be no movement. Proper reconnection ensures reliable electrical contact and prevents future corrosion buildup from poor connections.

Stop Battery Corrosion Before It Starts: Three Proven Methods

Install Chemical-Neutralizing Felt Washers

These specially treated washers absorb acid vapors before they reach terminal surfaces:

Installation Process:

1. Remove battery terminals

2. Place red (positive) and black (negative) felt washers over each post

3. Reattach terminals securely over the washers

Felt washers typically last through your battery’s lifespan but lose effectiveness over time. Replace them when you see white residue building up on the washers themselves.

Apply High-Temperature Terminal Protection

Silicone-based grease outperforms petroleum jelly by lasting longer under high temperatures and resisting chemical breakdown:

Application Method:

1. Coat felt washers with thin grease layer (if used)

2. Cover entire terminals completely—no bare metal should show

3. Fill side-post holes to prevent acid leaks and bolt seizing

The grease creates a waterproof barrier that blocks moisture and acid contact. Reapply during every maintenance check for maximum protection.

Create a Realistic Maintenance Schedule

Inspect your battery twice yearly—before summer heat and winter cold hit hardest. Increase frequency in:

– Extreme temperature areas (below 0°F or above 100°F)

– High humidity regions (coastal areas)

– Severe weather locations (frequent rain or snow)

During inspections, clean minor corrosion immediately with a dry wire brush and reapply protective grease. Older batteries (over 3 years) require more frequent monitoring as they’re prone to increased leakage.

When to Call a Professional Instead of Cleaning Yourself

When DIY cleaning reveals these severe issues, stop immediately and call a mechanic:

- Terminal replacement needed for heavily corroded connections that won’t accept cleaning

- Battery replacement required for swollen cases, visible leaks, or damaged cables

- Professional consultation essential when home methods fail to restore proper electrical function

Remember: proactive maintenance prevents severe corrosion that demands expensive professional repairs. Clean your battery terminals today, and you’ll avoid tomorrow’s roadside emergency. The 30 minutes you invest now could save you hundreds in towing fees and replacement parts later.

By following this exact process, you’ll transform your corroded battery connections into clean, reliable power sources that start your car every time. Don’t wait until you’re stranded—schedule your battery inspection today and keep your vehicle running smoothly through every season.