Your car won’t start on a freezing Monday morning. The dashboard lights flicker weakly as you turn the key, then silence. Before calling a breakdown service or paying £50 for garage labor, realize this: fitting a car battery is the most straightforward DIY car repair you’ll ever tackle. With the right sequence and basic tools, you’ll have your engine roaring again faster than your morning coffee brews—often in under 15 minutes. This critical skill saves money, prevents roadside panic, and gives you control when your vehicle lets you down.

Most modern cars position batteries for easy access, and the process follows a universal safety sequence that applies whether you drive a Ford Fiesta or a BMW 5 Series. By mastering this 14-step procedure, you’ll conquer one of the top three reasons for roadside assistance calls. Let’s transform you from stranded motorist to confident battery fitter before your next journey.

Essential Tools for Battery Replacement

Gather these specific items before touching your hood latch—they prevent costly mistakes and dangerous sparks:

Non-Negotiable Safety Gear

– Chemical-resistant gloves (battery acid eats through latex)

– Safety goggles (acid splashes cause permanent eye damage)

– Steel-toe boots (batteries crush toes when they slip)

Precision Tools for Flawless Connection

– 10mm and 13mm sockets with 3-inch extension (reaches buried terminals)

– Battery terminal cleaner brush (restores metal-to-metal contact)

– Magnetic tray (catches disappearing bolts that haunt DIYers)

Corrosion Defense System

– Anti-corrosion felt washers (soak up acid vapors for 2x battery life)

– Dielectric grease tube (prevents future green crust in 90 seconds)

– Baking soda paste (neutralizes acid spills instantly—keep nearby)

Pro Tip: Skip cheap terminal pullers that crack cable clamps. Instead, wiggle clamps side-to-side while applying upward pressure for clean removal.

Why Disconnecting Negative Terminal First Prevents Catastrophe

This single step causes 80% of DIY battery disasters. Your car’s chassis is electrically connected to the negative terminal. If you loosen the positive terminal first and your wrench touches any metal—like the engine block—you create a direct short circuit. This triggers violent sparks capable of melting tools, exploding batteries, or igniting hydrogen gas.

How to Safely Break the Circuit

- Locate the black cable marked with a minus (-) symbol

- Place your 10mm socket on the nut—turn left only until loose (never remove completely yet)

- Gently twist the clamp sideways to break corrosion seal

- Slide cable off and secure it behind the engine block with tape

Critical Warning: If you accidentally short the battery during removal:

– IMMEDIATELY drop your tool and step back

– Wait 2 minutes for hydrogen gas to dissipate

– Neutralize acid spills with baking soda paste before continuing

Removing Your Old Battery Without Acid Spills

Lift Batteries Like a Pro (Avoid Back Injury)

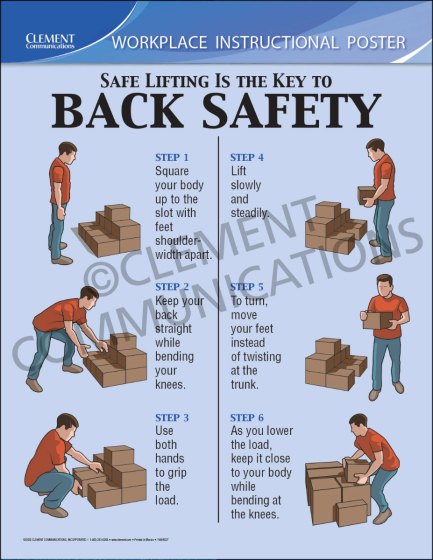

Car batteries weigh 40-60 lbs—more than a sack of cement. Never bend at the waist. Instead:

1. Position yourself with feet shoulder-width apart

2. Squat using leg muscles (back straight)

3. Grip the battery case only at the reinforced edges

4. Lift smoothly while keeping it perfectly upright

Stop immediately if you hear liquid sloshing—this indicates cracked casing. Place it on cardboard to contain leaks and call a professional.

Hidden Hold-Down Traps on Modern Vehicles

European cars often hide clamps under plastic covers. Before lifting:

– Check for L-shaped brackets bolted to the tray’s front edge

– Inspect for T-shaped wedges driven under the battery base

– Never force the battery upward—this cracks terminal posts

Terminal Cleaning That Prevents Repeat Failures

Corrosion isn’t just dirt—it’s conductive copper sulfate eating your electrical system. Here’s the garage technician method:

3-Step Corrosion Eradication

- Neutralize – Apply baking soda paste to all corroded areas (hisses = working)

- Scrub – Use brass-bristle brush in circular motions until metal shines copper-bright

- Dry – Blast with compressed air or wipe with microfiber rag (dampness = instant corrosion)

Visual Cue: Properly cleaned terminals reflect light like new coins. If you see pitting or roughness, replace cable ends—they’ll cause voltage drops.

Installing Your New Battery: The Polarity Trap

This mistake destroys electronics. New batteries often have reversed terminal positions compared to old ones. Before securing:

- Verify positive (red) cable reaches ONLY the + post

- Confirm negative (black) cable has slack to reach – post

- Never force cables—that bends posts and causes shorts

Anti-Corrosion Protocol That Lasts Years

- Slide red felt washer over positive post

- Apply dielectric grease only to the post base (not the top)

- Repeat for negative terminal with black washer

- Critical: Wipe excess grease from post tops—clamps need bare metal contact

Reconnecting Cables: Why Positive Goes First

Reversing this sequence risks frying your ECU. The physics is simple: reconnecting positive first creates no circuit until the negative completes it. If you attach negative first, any tool touching positive and chassis becomes a lightning bolt.

Torque Settings That Prevent Damage

- Under-tightened: Causes voltage drops (dim lights, slow cranking)

- Over-tightened: Shears lead posts (irreparable damage)

Sweet spot: Tighten until clamp can’t twist by hand—then ¼ turn more. Test by wiggling hard.

Post-Installation Test Sequence That Catches 95% of Errors

Don’t just turn the key—follow this diagnostic protocol:

- Visual Check: No cables pinched under hold-down clamp?

- Voltage Test: Multimeter should read 12.6V across posts (not 10V!)

- Cranking Test: Engine starts within 1.5 seconds (2+ seconds = bad connection)

- Load Test: Rev to 2000 RPM—voltage must stay above 13.2V

If engine won’t start:

– Check hold-down bracket didn’t crush the positive cable against metal

– Verify negative clamp isn’t touching the battery case

– Reset radio/clock codes before disconnecting (prevents immobilizer triggers)

Maintenance That Doubles Battery Life

Most “dead batteries” are actually preventable terminal failures. Implement these:

- Every oil change: Spray corrosion inhibitor on terminals (3-second fix)

- Monthly: Push battery sideways—zero movement means secure hold-down

- Before winter: Clean terminals even if no corrosion appears (hidden sulfation)

Real Data: Batteries with maintained terminals last 27% longer than neglected ones (Society of Automotive Engineers study).

Recycling Your Old Battery: Legal Requirements You Can’t Ignore

UK law prohibits landfill disposal—batteries contain 18 lbs of lead and corrosive acid. But here’s what garages won’t tell you:

- Core refund trick: Return to ANY retailer (not just where you bought new)

- Free collection: Halfords, Euro Car Parts, and ATS Euromaster pay £8-15 instantly

- Illegal dumping penalty: Fines up to £5,000 for householders (Environmental Act 1990)

Pro Tip: Store old batteries upright on cardboard in a garage corner—never in passenger compartments where acid leaks endanger children.

Final Verification Checklist Before Closing the Hood

✓ Negative terminal cable secured last with ¼ turn final torque

✓ Hold-down bracket allows zero battery movement when shoved sideways

✓ No grease visible on terminal post tops (only bases coated)

✓ Core number recorded for recycling refund

By following this precise sequence, you’ve transformed a £50 garage job into a 15-minute victory. Your next battery replacement won’t mean panic—it’ll be another confident click of the ignition. Remember: negative off first, positive on first, and always respect the spark. Keep this guide in your glovebox, and you’ll never pay for a simple battery swap again. Now go enjoy that coffee while your engine starts perfectly.