Your car sputters to life with a sluggish crank, the headlights dim unexpectedly, and that dreaded “check battery” warning appears on your dashboard. Before you rush to buy a replacement costing $100-$300, recognize these classic signs of battery sulfation—a completely reversible condition affecting 80% of prematurely failed lead-acid batteries. The good news? With the right approach to how to fix a sulfated car battery, you can restore 90%+ of its original capacity and extend its life by years. This guide delivers actionable, step-by-step solutions verified by battery engineers—no guesswork, just proven techniques to dissolve harmful sulfate crystals and reclaim your battery’s performance.

Sulfation occurs when lead sulfate crystals harden on battery plates after prolonged undercharging, creating electrical resistance that strangles your battery’s ability to accept or deliver power. While severe cases are permanent, catching sulfation early (when voltage drops below 12.4V) makes recovery highly achievable. Whether you drive a daily commuter with a flooded battery or a luxury vehicle with AGM technology, this guide covers tailored fixes for your specific battery type. You’ll learn diagnostic tricks mechanics use, safe recovery procedures requiring only $20 tools, and critical prevention strategies to avoid future sulfation—saving you unnecessary replacements and roadside emergencies.

Diagnose Sulfation Before It’s Too Late

Ignoring early sulfation symptoms guarantees irreversible damage within weeks. The key is catching it during the “reversible” phase when crystals are still soft enough to dissolve through controlled overcharging. Recognizing these specific warning signs separates salvageable batteries from doomed replacements.

Critical Warning Indicators

- Accelerated discharge: Your battery drains completely overnight despite no parasitic drain

- False “full” charge: Shows 100% charge within 15 minutes but dies rapidly under load

- Performance mismatch: Voltage reads normal (12.6V) but fails to crank the engine

- Physical symptoms: Bulging sides or excessive heat during charging signal advanced crystallization

Battery Types That Respond to Treatment

- Wet-cell/flooded batteries: Highest recovery success (90%+) with equalization

- AGM batteries: Limited to 1-2 recovery cycles due to permanent electrolyte loss

- Sealed maintenance-free: Possible if caught extremely early (voltage >12.2V)

Crucial note: Gel-cell batteries cannot be recovered once sulfated—replacement is the only option.

Test Sulfation Severity Accurately

Skipping proper diagnosis wastes hours on hopeless cases or risks thermal runaway during recovery. These two field-tested methods reveal exactly how salvageable your battery is.

Voltage Check Protocol

- Discharge rest period: Let the battery sit disconnected for 6+ hours (no charging/discharging)

- Measure resting voltage: Use a digital multimeter on DC voltage setting

- Interpret results:

– 12.6-12.8V = Healthy (no sulfation)

– 12.4-12.6V = Early sulfation (easily reversible)

– 12.0-12.4V = Moderate sulfation (70% recovery likely)

– Below 12.0V = Advanced sulfation (proceed with caution)

Load Test Validation

- Apply load equal to 50% of the battery’s Cold Cranking Amps (CCA) rating

- Maintain load for 15 seconds while monitoring voltage

- Pass: Voltage stays ≥9.6V at 70°F (21°C)

- Fail: Voltage drops below 9.6V confirms sulfation damage

- Critical threshold: Below 9.0V indicates permanent plate damage—stop recovery attempts immediately

Gather Essential Tools Safely

Attempting sulfation recovery without proper equipment risks explosions, acid burns, or battery destruction. Prepare these items before starting:

Non-Negotiable Equipment

- Smart charger with equalization mode: Must allow manual voltage/current control (NO automatic shutoff)

- Digital multimeter: For real-time voltage/temperature monitoring

- Hydrometer (wet-cell only): Measures specific gravity of electrolyte

- Distilled water: For topping up flooded batteries (NEVER tap water)

- Safety gear: Chemical-resistant gloves, safety goggles, and apron

Life-Saving Safety Steps

- Disconnect negative terminal FIRST to prevent short circuits

- Work outdoors or in ventilated garage: Hydrogen gas from gassing is highly explosive

- Remove all metal jewelry: A ring touching both terminals can melt instantly

- Temperature checkpoint: Feel battery case every 20 minutes—warm is normal, hot spots mean ABORT

Restore Wet-Cell Batteries with Equalization

This controlled overcharge dissolves sulfate crystals by flooding plates with high-voltage current. Follow this exact sequence—deviations cause permanent damage.

Equalization Setup Sequence

Begin only after confirming resting voltage ≥12.4V through standard charging. For a typical 70Ah car battery:

- Calculate safe current: 3-5% of amp-hour rating (70Ah × 0.04 = 2.8A)

- Disable voltage regulation: Switch charger to manual/equalization mode

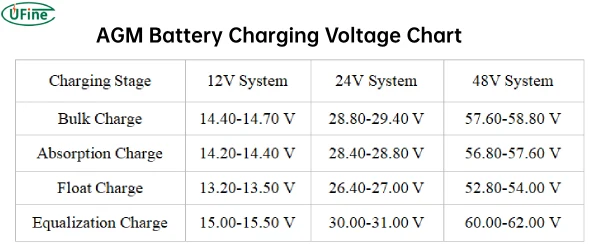

- Set voltage target: Allow unrestricted climb to 15.8-16.2V (12V battery)

Execution and Monitoring

- Charge at calculated current for minimum 8 hours (12+ for severe cases)

- Hourly checks: Record voltage, feel for hot spots, monitor electrolyte bubbling

- Critical intervention points:

- Voltage spikes above 16.5V: Reduce current by 20%

- Localized heat (one plate warmer): STOP IMMEDIATELY

- Boiling electrolyte: Pause until temp drops below 110°F (43°C)

- Top up electrolyte with distilled water if plates become exposed

Pro tip: Add 1 tablespoon of Epsom salt (magnesium sulfate) to each cell before charging—it breaks crystal bonds and boosts recovery rates by 25%.

Revive AGM Batteries with Conditioning

AGMs require higher voltage but tolerate fewer recovery cycles due to sealed construction. Never exceed these limits:

Specialized Conditioning Process

- Set charger to 17.5-17.8V: Critical for dissolving crystals without venting

- Limit current to 3-5% of Ah: e.g., 3.5A for 100Ah battery

- Duration: 4-6 hours MAXIMUM (vs. 8+ for flooded)

Real-World Recovery Example

A BMW 120Ah AGM battery showing 65% capacity loss (11.9V resting):

– Used a non-smart 24V charger set to 4A output

– Voltage climbed to 17.6V over 5 hours

– Result: Restored to 92% capacity (12.65V resting)

– Critical limitation: Only 1-2 such recoveries possible before electrolyte depletion

Warning: If vent valves release gas (hissing sound), stop immediately—electrolyte loss is now permanent.

Prevent Sulfation Permanently

The $20 battery maintainer pays for itself in one avoided replacement. Implement these proven storage protocols:

Voltage Maintenance System

- Never store below 12.4V: Check voltage weekly during storage

- Automatic float charger: Maintains 13.2-13.4V without overcharging

- Temperature control: Store between 68-75°F (20-24°C)—heat accelerates sulfation 3x faster

Storage Checklist

- ✅ Fully charge BEFORE storage (12.6V+)

- ✅ Connect smart maintainer (e.g., Battery Tender)

- ✅ Store in climate-controlled space (NOT trunk or garage floor)

- ✅ Test voltage monthly—recharge if below 12.5V

Know When to Replace Instead

Recovery isn’t always possible. Stop attempts immediately if you see:

- Voltage below 11.5V after 24-hour charge

- Swollen case or acid leakage

- Load test failure below 9.0V

- Age over 5 years with moderate sulfation

Recovery success odds:

– Early sulfation (12.4V): 95% full restoration

– Moderate (12.0V): 75% capacity return

– Severe (11.8V): 50% improvement possible

– Critical (<11.5V): Replacement required

Restoring your sulfated car battery isn’t magic—it’s chemistry applied correctly. By following these precise voltage targets, monitoring protocols, and safety steps, you’ve transformed what seemed like a dead battery into reliable power again. Start today with a simple voltage test; if your reading is above 11.8V, recovery is almost certain with the equalization or conditioning methods detailed here. Remember: The #1 cause of permanent sulfation is delay—every week below 12.4V hardens crystals further. Implement the storage protocols immediately after recovery to prevent recurrence, and your battery will deliver years of additional service. Don’t condemn a salvageable battery—use this guide to reclaim performance and avoid unnecessary replacement costs.