Your headlights are flickering erratically, a pungent rotten egg smell wafts from under the hood, and you notice your battery case looks suspiciously swollen. These aren’t isolated issues—they’re unmistakable symptoms of an overcharged car battery, a serious electrical malfunction that can leave you stranded or cause dangerous under-hood explosions. When your vehicle’s charging system pushes voltage beyond 14.7 volts, excess energy transforms into heat and explosive hydrogen gas, threatening both your safety and your wallet.

Most drivers don’t realize that sustained voltage above 15.0 volts means your alternator is flooding your battery with dangerous levels of electricity. This comprehensive guide delivers proven techniques to diagnose, fix, and prevent overcharged batteries—methods that could save you hundreds in unnecessary repairs and avoid potentially catastrophic damage to your vehicle’s electrical system.

Identify Overcharging Symptoms Before Damage Escalates

Rotten Egg Smell Means Immediate Action Required

That distinctive sulfur odor isn’t just unpleasant—it’s hydrogen sulfide gas escaping from boiling battery acid. When you detect this smell combined with these critical symptoms, shut off your engine immediately to prevent further damage:

- Bulging battery case – swelling more than 3mm above the base indicates dangerous internal pressure

- Electrolyte leaks around cell caps or terminals that leave white or blue corrosion

- Flickering lights that change intensity with engine speed

- Frequently blown bulbs in headlights or interior lighting

- Illuminated battery warning light that stays on after engine start

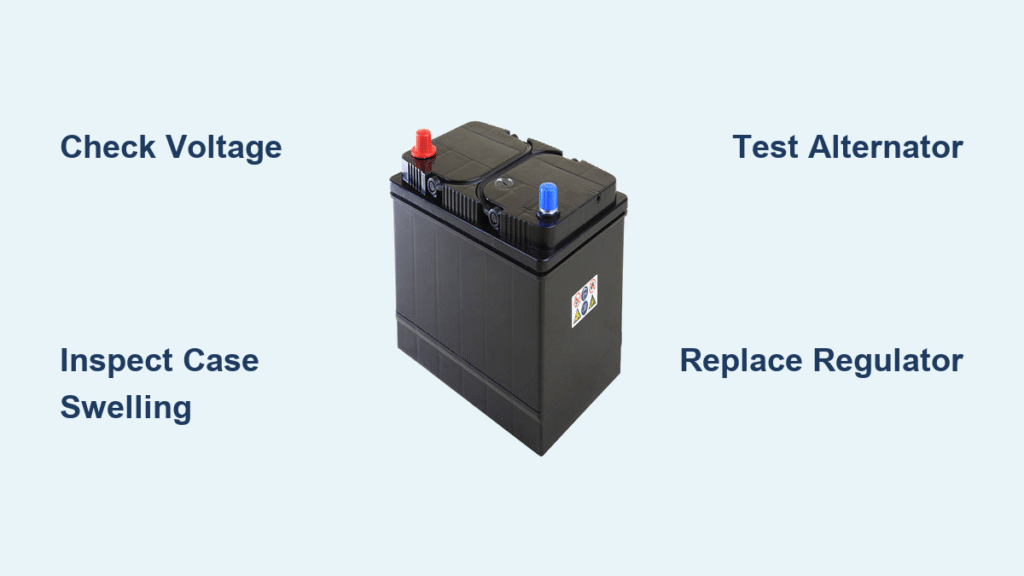

30-Second Visual Inspection Protocol

Before attempting any repairs, perform this rapid safety assessment:

- Examine for battery case distortion – any visible swelling means the battery must be replaced

- Check for acid corrosion on terminals and surrounding metal components

- Inspect vent caps for moisture or dried electrolyte residue

- Note any discolored or warped plastic around battery vents indicating heat damage

Confirm Overcharging with Voltage Testing

Multimeter Diagnosis Procedure

A simple multimeter test provides definitive proof of overcharging and takes less than five minutes:

Engine Off Test:

– Wait 30 minutes after shutting off your engine

– Connect multimeter probes to battery terminals

– Reading should be 12.4-12.6 volts

– Below 12.4 volts indicates undercharge, not overcharge

Engine Running Test:

– Start engine and let it idle for 2 minutes

– With no electrical loads active, voltage should read 13.5-14.5 volts

– 14.6-14.9 volts = borderline high, requires immediate monitoring

– 15.0+ volts = confirmed overcharging demanding urgent action

Load Test:

– Turn on headlights, rear defroster, and blower motor

– Voltage should remain 13.5-14.5 volts under full electrical load

– Failure to drop indicates regulator malfunction forcing constant maximum output

OBD-II Scanner for Modern Vehicles

Your vehicle’s computer stores charging system faults as diagnostic trouble codes:

- P0560 = System voltage out of range (most common overcharging code)

- P0622 = Generator field control circuit malfunction

- Live data showing alternator duty cycle exceeding 90% at idle confirms regulator failure

Emergency Shutdown Procedures for Safety

Immediate Response Protocol

When overcharging is confirmed, follow these critical safety steps in sequence:

- Shut off engine immediately – stops further voltage escalation

- Disconnect external chargers – remove all power sources

- Open hood fully – allows dangerous hydrogen gas to dissipate

- Put on safety gear – nitrile gloves and eye protection are mandatory

- Wait 30 minutes – lets battery temperature stabilize before handling

Critical Safety Warning: Never attempt to remove battery caps while the case feels warm. Boiling electrolyte can spray sulfuric acid under pressure, causing severe chemical burns to skin and eyes.

Pinpoint the Root Cause Accurately

Alternator Regulator Failure Diagnosis

Most overcharging stems from a faulty voltage regulator inside the alternator. Modern regulators fail when:

- Internal transistors short circuit from heat exposure

- Carbon brushes wear beyond 4mm length, losing contact

- Moisture or corrosion damages regulator circuitry

- Poor ground connections create false voltage readings

External Charger Mistakes Analysis

Many overcharging incidents originate from improper charger use:

- Using 16+ volt settings on standard 12-volt batteries

- Leaving conventional chargers connected for extended periods

- Selecting high-amp boost mode for routine maintenance charging

- Using automotive chargers on sensitive sealed AGM batteries

Repair the Charging System Effectively

Regulator Replacement Process

Replacing just the voltage regulator costs 75% less than a new alternator:

Skill Level: Advanced DIY (requires soldering experience)

Time Required: 2-3 hours

Cost: £25-£60 for regulator kit vs £250 for new alternator

Critical Steps:

1. Remove alternator from vehicle using proper belt tensioner tools

2. Document brush positions before disassembly for correct reinstallation

3. Carefully desolder old regulator from brush assembly

4. Install new regulator with proper heat sink compound

5. Replace carbon brushes if worn below 4mm length

Expert Insight: “We’ve seen blown bulbs quickly escalate to fried engine control units,” warns certified technician Scott Greensmith. “Fix that regulator immediately before a £50 problem becomes a £500 nightmare.”

Complete Alternator Replacement Guide

When regulator replacement isn’t practical, consider these options:

DIY Replacement:

– Cost: £90-£200 for remanufactured unit

– Time: 1-2 hours for experienced mechanics

– Requires: Proper torque wrench, belt tensioner tool, battery disconnect

Professional Installation:

– Cost: £250-£400 fitted with labor

– Includes: Comprehensive system retest and warranty coverage

– Recommended for: Internal regulator failures, seized bearings, or complex installations

Determine Battery Salvageability

State-of-Health Assessment

Use these tests to determine if your battery can be saved:

Conductance Test:

– Available free at most auto parts stores

– <70% of rated CCA = battery must be replaced

– Provides instant health reading in 30 seconds

Specific Gravity Test (flooded batteries only):

– All cells should read 1.265-1.275 at 27°C

– >0.050 variation between cells indicates irreversible damage

– Requires proper hydrometer and safety precautions

Recovery Procedures by Battery Type

Flooded Lead-Acid (Serviceable):

– If salvageable: Carefully top up with distilled water to lower level mark

– Slow charge at 0.1C rate (10A for 100Ah battery) for 12-24 hours

– Equalize charge at 15.5 volts for 2 hours to balance cells

– Replace if: Case distortion, capacity loss >30%, or cell failure

Sealed/AGM/EFB:

– No electrolyte access – replacement is only option if damaged

– Replace immediately if: Swelling, capacity <70%, or any physical damage

– Recycle properly at certified facility for core refund

Prevent Future Overcharging Incidents

Smart Charging Technology Solutions

Invest in these charging solutions to prevent recurrence:

- Microprocessor-controlled multi-stage chargers with automatic shutoff

- Float mode that maintains battery without overcharging

- Temperature compensation that adjusts for ambient conditions

- Battery-specific profiles for AGM, EFB, or standard lead-acid

Proactive Maintenance Schedule

Prevent problems with these simple routines:

- Every oil change: Test charging system voltage at idle and under load

- Before winter: Conduct thorough battery load test and check connections

- After jump-starts: Verify charging system function to catch regulator damage

- When installing accessories: Ensure electrical system capacity supports new loads

8-Step Emergency Response Plan

When you suspect overcharging, follow this critical sequence:

- Confirm voltage exceeds 15.0 volts while engine is running

- Stop all charging sources immediately (shut off engine)

- Inspect battery for physical damage before handling

- Test alternator and regulator function with multimeter

- Replace faulty regulator or entire alternator as needed

- Re-test system voltage under all electrical loads

- Replace battery if capacity <70% or showing physical damage

- Check entire electrical system for collateral damage to fuses and wiring

Overcharging represents more than an inconvenience—it’s a serious safety hazard that can cascade into expensive electrical damage throughout your vehicle. By recognizing warning signs early and following systematic diagnostic procedures, you can resolve the problem efficiently while preventing future occurrences. Remember, when hydrogen gas risks or complex electrical issues are present, professional service costs far less than emergency room visits or dealing with engine bay fires. The key to avoiding costly repairs is prompt action at the first sign of trouble—your safety and your wallet will thank you.