Your engine sputters but won’t turn over, or you hear that ominous single click instead of ignition. Before you panic about a dead battery, know this: 70% of “no-start” cases stem from faulty battery connections, not the battery itself. Corrosion, loose clamps, or damaged cables sabotage power flow even with a fully charged battery. The best part? Most how to fix car battery connection issues take under 30 minutes with basic tools you likely own. This guide delivers precise, step-by-step fixes—from a quick tightening trick to full cable replacement—so you can diagnose and solve connection problems like a pro mechanic.

Match Your Symptoms to the Right Fix

Don’t waste time on unnecessary repairs. Pinpoint your exact issue using these real-world failure signs:

- Single loud click when turning the key? → High-resistance corrosion or loose clamp blocking power to the starter

- Car starts after wiggling cables? → Vibration-loose connection (common after hitting bumps)

- Headlights dimming while driving? → Intermittent connection starving your electrical system

- White/green crust around terminals? → Acid corrosion creating electrical resistance

If your battery case shows cracks, leaks, or bulging, stop immediately—replace the battery first. Connection fixes won’t help a failing battery.

Critical Safety Steps Before You Start

Skipping these risks acid burns, electrical shorts, or explosions:

- Engine OFF, key out, parking brake engaged—never work on live circuits

- Remove negative (black) cable FIRST, then positive (red)—reconnect in reverse order

- Wear acid-resistant gloves and sealed goggles—battery acid causes severe eye damage

- Remove metal jewelry—rings or bracelets can spark against tools, melting instantly

- Work in open air—batteries vent explosive hydrogen gas; no smoking or sparks nearby

Pro Tip: Place disconnected cables where they can’t accidentally touch metal surfaces. A dropped wrench bridging positive and ground can melt like lava.

Must-Have Tools for Fixing Battery Connections

| Tool | Why It’s Non-Negotiable |

|---|---|

| 8mm or 10mm wrench/socket | Standard bolt sizes on 95% of vehicles |

| Brass-wire brush | Cleans corrosion without scratching soft lead posts |

| Baking soda + water (1 tbsp/cup) | Neutralizes acid safely (vinegar worsens corrosion) |

| Dielectric grease | Seals out moisture—petroleum jelly degrades in heat |

| Terminal shim kit | Fixes stretched clamps (soda-can aluminum works temporarily) |

Skip the specialty cleaner: A stiff-bristled toothbrush and baking soda paste work for light corrosion. But never use steel wool—it creates conductive debris.

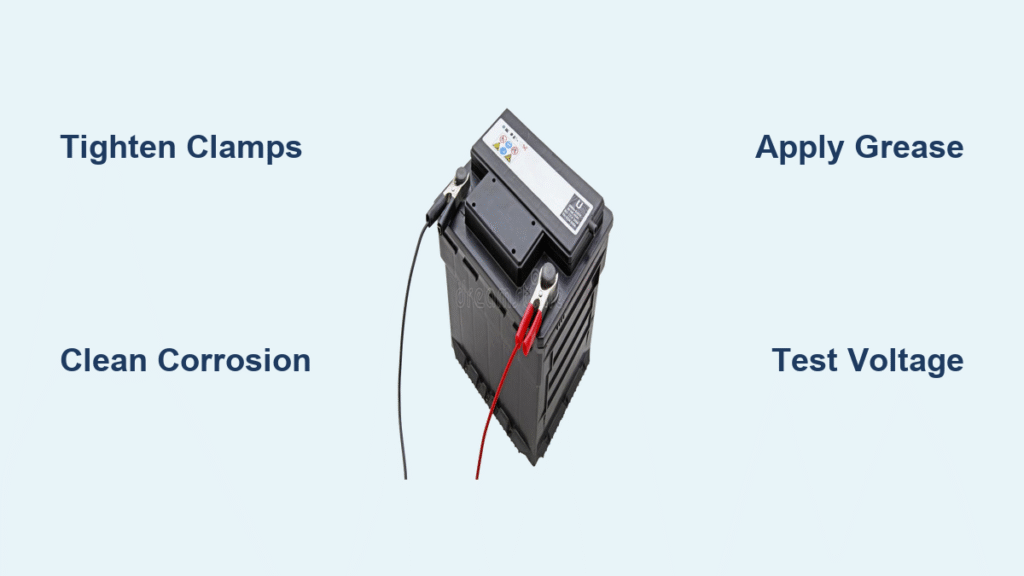

Tighten Loose Connections in 5 Minutes Flat

This fixes 40% of “dead battery” scares:

- Test for looseness: Grab each cable near the clamp and twist. If it moves more than 2mm (1/8 inch), it’s too loose

- Hold the cable steady with one hand to prevent wire twisting

- Tighten the clamp bolt clockwise until snug, then give one-eighth extra turn—no more! Over-tightening strips soft lead posts

- Verify: Clamp shouldn’t budge when you press firmly with your thumb

Warning: If the bolt bottoms out but the clamp still rocks, you need shims—not brute force. Forcing it cracks the terminal.

Eliminate Corrosion That’s Killing Your Connection

Heavy white/green crust requires this 20-minute deep clean:

Disconnect Without Sparking

- Always remove negative (black) cable first, then positive (red)

- Isolate cables so clamps can’t touch metal surfaces

Neutralize and Scrub Properly

- Sprinkle dry baking soda over corrosion until covered

- Dribble water slowly—it will fizz as acid neutralizes

- Scrub posts and clamp interiors with brass brush until shiny metal shows

- Wipe residue with damp rag, then dry thoroughly with paper towels

Reconnect Without Recontamination

- Apply thin dielectric grease layer to post and clamp interior (thick globs trap heat)

- Attach positive cable first, then negative—snug bolts to 5-7 N·m (hand-tight plus 1/8 turn)

Expert Note: Green corrosion under cable insulation means internal wire damage—replace the cable immediately.

Fix Wobbly Clamps with Shims (No Replacement Needed)

When tightening fails because the clamp is stretched:

- Clean post and clamp until bare metal shows

- Cut 0.02-inch brass shim (or soda-can aluminum) into a strip

- Wrap shim once around the battery post—overlap ends slightly

- Slide clamp over shim/post and tighten bolt until snug

- Trim excess shim flush with clamp edge using snips

Why brass? Aluminum corrodes faster. Pre-cut shim kits ($3 at auto stores) outlast DIY fixes by 2+ years.

Replace Only the Damaged Terminal Clamp

Do this if the clamp is cracked, melted, or stripped:

Prepare the Cable

- Cut old clamp off with cable cutters as close as possible

- Strip ½ inch (13mm) of insulation—don’t nick copper strands

- Pull strands straight so they fit fully into the new clamp

Secure the New Connection

- For screw clamps: Insert cable until insulation touches barrel, then tighten screws evenly

- For crimp clamps: Use proper ratcheting crimper—hammer-crimping creates weak spots

- Critical check: 1/8 inch of bare wire must show beyond the barrel for inspection

Time Saver: Match the clamp size to your cable gauge—6 AWG for cars, 4 AWG for trucks. Wrong sizes cause overheating.

Replace Entire Cables When Corrosion Creeps Inside

Replace full cables if you see:

– Green corrosion under insulation

– Brittle, stiff, or melted cable sections

– Multiple repair attempts shortening the cable

Installation Checklist

- Photograph original routing—cables follow specific paths to avoid heat sources

- Disconnect at the far end first: Starter/solenoid (positive) or engine block (negative)

- Remove all protective loom and clips—reinstall on new cable

- Route new cable identically—never stretch or kink

- Connect battery end LAST (negative always goes on last)

Pro Tip: Match OEM cable gauge exactly. Undersized cables cause voltage drops; oversize ones won’t fit clamps.

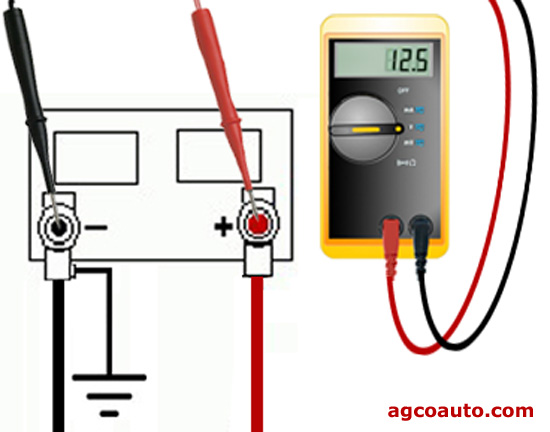

Verify Your Fix with 3 Critical Tests

Don’t assume it’s working—prove it:

- Physical test: Tug cables firmly—zero movement at clamps

- Visual check: No gaps between post and clamp; all surfaces coated with dielectric grease

- Voltage drop test:

- Set multimeter to DC volts

- Probe battery post (+) and clamp (+) simultaneously

- Crank engine—reading must stay below 0.2V (higher = poor connection)

If voltage drops exceed 0.2V, repeat cleaning or replace clamps. A healthy connection shows 12.4-12.6V engine-off and 13.8-14.4V running.

Prevent Repeat Failures with Smart Maintenance

Make connection issues vanish for years:

- Every oil change (5,000-7,500 miles):

- Quick visual inspection for early corrosion

- Retighten bolts if needed (lead posts settle over time)

- Every 6 months:

- Full cleaning with wire brush

- Reapply dielectric grease to posts/clamps

- When installing new batteries:

- Always clean terminals first—never slap on new clamps over corrosion

Critical Insight: Green corrosion under insulation means acid penetrated the cable—replace immediately to avoid fire risks.

When to Call a Professional Immediately

Stop DIY repairs if you see:

– Battery posts spinning inside the case (internal failure imminent)

– Cracks or acid leaks from the battery casing

– Melted cable insulation (indicates dangerous charging system faults)

– Electronics resetting after your fix (points to deeper wiring issues)

These signal complex electrical problems beyond simple connection fixes. A mechanic can diagnose alternator faults or wiring harness damage that DIY methods miss.

A rock-solid battery connection means reliable starts for years. By mastering these targeted fixes—from 5-minute tightening to precision corrosion cleaning—you’ll solve 90% of “no-start” emergencies faster than a tow truck arrives. Remember: always disconnect negative first, use dielectric grease religiously, and verify with voltage tests. Keep this guide in your glovebox, and you’ll never pay $150 for a $15 connection fix again. For persistent issues, consult a professional—your safety is worth more than any shortcut.