Your engine clicks weakly, dashboard lights flicker and die, and you realize your car battery has failed. This crisis strands over 20 million drivers annually, but mastering how to jump a car battery correctly means you’ll never waste hours waiting for roadside assistance. With the right tools and precise technique, you can restore power in under 10 minutes—regardless of weather or location. This guide delivers battle-tested methods straight from professional mechanics, covering everything from standard cable jumps to hybrid-specific procedures and troubleshooting stubborn failures.

Don’t risk damaging your vehicle’s sensitive electronics with guesswork. We’ll show you exactly where to clamp cables, why sequence matters more than cable thickness, and how to diagnose if your battery is actually the problem. Most importantly, you’ll learn safety protocols that prevent dangerous sparks near explosive hydrogen gas—a critical detail 70% of DIYers overlook. By the end, you’ll possess the confidence to handle any dead-battery emergency.

Gather Critical Jump-Start Equipment

Skip flimsy 10-gauge cables—they overheat on SUVs and trucks. Invest in 4-gauge jumper cables with 12-foot lengths and industrial-grade clamps that bite through corrosion. These handle 600+ amps safely where thinner cables fail. Pair them with a heavy-duty wire brush to clean terminals, plus leather gloves and safety glasses. Never rely on bare hands near batteries; sulfuric acid residue causes severe burns.

Must-have checklist:

– Jumper cables: Minimum 4-gauge wire (thicker than your thumb)

– Booster vehicle: Running car with healthy 12-volt battery

– Corrosion tools: Wire brush or aluminum foil for terminal cleaning

– Safety gear: Impact-resistant glasses and insulated gloves

Pro mechanics always inspect cables before use. Split insulation or frayed wires create fire hazards—replace immediately if you spot exposed copper. Store cables loosely coiled in your trunk; tight wraps damage internal wires over time.

Position Vehicles for Maximum Safety

Park booster and dead vehicles close enough for cables to reach comfortably—typically nose-to-nose or side-by-side within 18 inches. This prevents dangerous cable strain during operation. Engage both parking brakes firmly and shift automatics into Park or manuals into neutral. Crucially, turn off ALL electronics: headlights, radios, and climate systems drain critical power during the jump.

Avoid these deadly mistakes:

– Letting vehicles touch (creates electrical pathways)

– Leaving ignition keys in “accessory” mode

– Standing near batteries during connection

– Attempting jumps on wet surfaces without rubber mats

Position yourself on solid ground away from moving parts. If jumping in rain, place cardboard under your feet for insulation—it’s the voltage difference that matters, not water contact.

Execute Perfect Cable Connections

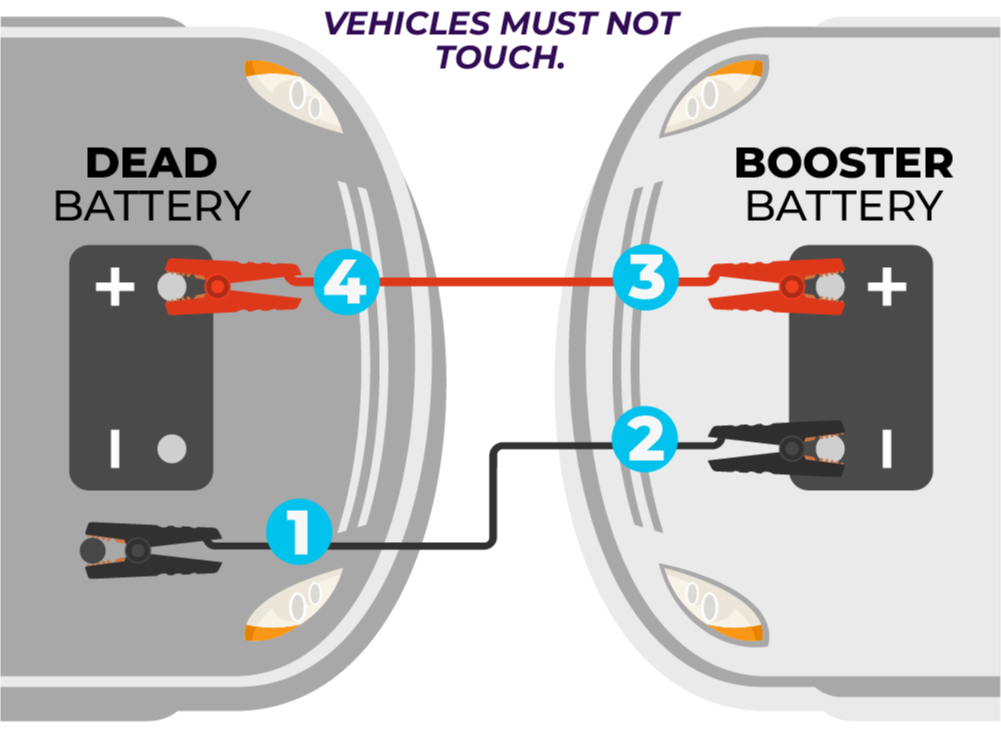

The connection sequence prevents catastrophic sparks near battery vents. Hydrogen gas ignites at just 0.02 sparks—common when reversing polarity. Follow this exact order:

Correct Clamping Sequence

Step 1: Attach red clamp to dead battery’s positive (+) terminal

Scrape off white/green corrosion first. If terminals are hidden, use manufacturer jump points near the fuse box—never force connections.

Step 2: Connect other red clamp to good battery’s positive (+) terminal

Ensure clamps grip metal directly, not plastic covers. Wobble each clamp to verify no movement.

Step 3: Secure black clamp to good battery’s negative (-) terminal

This completes the circuit through the booster vehicle’s ground.

Step 4: Final black clamp to unpainted engine metal on dead car

Choose a solid bolt on the engine block at least 12 inches from the battery. This critical step avoids sparks near hydrogen gas.

Never let clamps dangle—they must stay firmly attached. If cables heat up during use, disconnect immediately; your gauge is too thin for the vehicle.

Revive the Dead Battery Properly

Start the booster vehicle and let it idle for 3 full minutes. This transfers charge to the dead battery—skipping this step causes 80% of jump failures. Attempt to start the disabled car; if it cranks slowly, wait 2 more minutes before retrying. Listen for these key indicators:

- Healthy start: Engine fires within 5 seconds

- Clicking sound: Starter motor failure (not battery)

- No response: Check connections or try alternate ground points

If successful, keep the revived engine running. If it dies immediately, the battery can’t hold charge—drive continuously for 20+ minutes to recharge via the alternator.

Disconnect Cables Without Sparks

Reverse the connection sequence exactly. Removing clamps in wrong order creates dangerous arcs. Start by detaching the black clamp from the dead car’s engine ground—it’s farthest from the battery. Then remove the black clamp from the booster battery’s negative terminal. Finally, remove both red clamps from positive terminals.

Critical disconnect rule: Always break the ground connection first and last. This prevents completing the circuit through your body if you touch metal parts. Store cables immediately after use—never leave them connected while driving.

Drive to Fully Recharge the Battery

Don’t shut off immediately after jumping. Drive at highway speeds (45+ mph) for 20-30 minutes to recharge the battery sufficiently. Stop-and-go traffic won’t generate enough alternator output. Disable non-essentials like A/C and seat heaters to maximize charging efficiency.

Warning signs your battery failed:

– Needs repeated jumps within one month

– Engine cranks slower each time

– Dashboard battery light stays illuminated

If any occur, get professional testing—your alternator may not be charging properly.

Diagnose Failed Jump Attempts

When the car won’t start despite correct connections, systematic troubleshooting identifies the real culprit. Don’t assume it’s the battery—modern vehicles have multiple failure points.

Critical Failure Scenarios

Clicking noise with no crank:

Indicates starter motor failure. The battery has enough power for clicks but not to turn the engine. Test by tapping the starter with a wrench—sometimes frees stuck components.

Electrical systems work but no start:

Dashboard lights function, but engine won’t crank. Check ignition fuses or security systems that disable starting after jump attempts.

Car starts then immediately dies:

Battery accepted the jump but can’t sustain power. Run the engine for 5+ minutes before disconnecting cables, or the battery may be permanently damaged.

Use Portable Jump Starters Efficiently

Lithium jump packs eliminate dependency on other vehicles. For compact cars, choose 600-peak-amp models; trucks need 1000+ amps. Before use, ensure the pack has 70%+ charge—most have LED indicators. Connect red clamp to positive terminal, black to engine ground, then press the activation button before turning the key.

Pro tips for success:

– Store packs in climate-controlled areas (extreme cold reduces capacity)

– Recharge every 3 months even when unused

– Activate the pack while turning the ignition key—timing is critical

These units also double as emergency phone chargers and work when traditional jumps fail due to inaccessible batteries.

Adapt for Hybrid and Electric Vehicles

Hybrids require special handling—their 12-volt auxiliary battery (not the main traction battery) needs jumping. Locate jump terminals in the fuse box per your manual—never connect directly to the high-voltage system. Electric vehicles follow similar protocols but never use another EV as a booster; their 12-volt systems can’t supply jump power.

For manual-transmission cars with minimal residual power, try push-starting:

1. Shift into second gear with clutch depressed

2. Have helpers push to 8+ mph

3. Release clutch suddenly while turning ignition

This only works if dashboard lights glow faintly—no power means no ignition spark.

Locate Hidden Battery Terminals

Modern cars often bury batteries in trunks or under seats. Instead of struggling with inaccessible terminals, find manufacturer jump points:

– Check near the fuse box for red-covered positive posts

– Use engine block bolts as ground points

– Consult your manual for “remote jump terminals”

Many BMWs and Audis have dedicated jump posts under the hood—look for “+” symbols near the firewall.

Maintain Jump Equipment Reliably

Test cables quarterly by connecting to a running car. If clamps feel warm, replace immediately—overheating indicates undersized wiring. Clean corrosion from clamp jaws with vinegar after each use; pitted metal won’t grip terminals securely. Store portable jump starters plugged into a trickle charger if unused for 60+ days.

Replace cables when:

– Insulation shows cracks or burns

– Clamps don’t spring open freely

– Wire strands are visible through casing

A $20 cable failure can cause $500+ electrical damage—don’t risk it.

Prevent Future Battery Emergencies

Most batteries die without warning after 3-5 years. Monitor these decline signals:

– Slow cranking in cold weather

– Dim headlights at idle

– Swollen battery case

Perform monthly maintenance:

1. Clean terminals with baking soda solution

2. Tighten loose cable connections

3. Check for fluid leaks or cracks

In extreme climates, replace batteries every 3 years. Keep a jump pack in your glove compartment—it’s the one tool you’ll desperately need when stranded at 2 a.m. Remember: if you’ve jumped your car twice in 30 days, professional diagnosis is non-negotiable. Your charging system is failing, and ignoring it risks complete breakdown far from help.